Hangzhou Meidong Sports Goods Co., Ltd., a company specializing in professional-grade leather volleyball production while catering to the needs of all age groups, offers both the core product line of WELLMAN machine-applied volleyballs for advanced players and basic sewn volleyballs for beginners. This article breaks down the differences between these two manufacturing processes and their suitable application scenarios to help you accurately choose the ball that best suits your needs.

I. Manufacturing Process: The Difference Between Traditional Sewn vs. CNC Thermal Bonding

The splicing process directly determines the final texture and basic performance of the volleyball, serving as a core indicator of its positioning. Hangzhou Meidong Sports has also developed corresponding product lines to meet different needs:

● Sewn-stitched Version:

Sewn stitching is a classic splicing technique for volleyballs and a basic product line from Hangzhou Meidong Sports, targeting entry-level users. The core process primarily involves “manual + semi-automated sewing”:

Fabric Cutting: Basic rubber/ordinary PU fabric is cut into 8-12 standard sheets;

Manual Sewing: Standardized training is provided by sewing workers who use industrial sewing machines to sew the sheets together one by one, controlling basic alignment errors;

Shell Turning and Shaping: The sewn shell is turned inside out, air valves are installed, and inflation is performed. The surface curvature is then manually adjusted;

Quality Control Testing: Each sewn-stitched volleyball undergoes basic airtightness and elasticity tests to ensure it meets daily usage needs before leaving the factory.

This product line is characterized by a mature production process, cost-effectiveness, and suitability for basic use scenarios with low budgets.

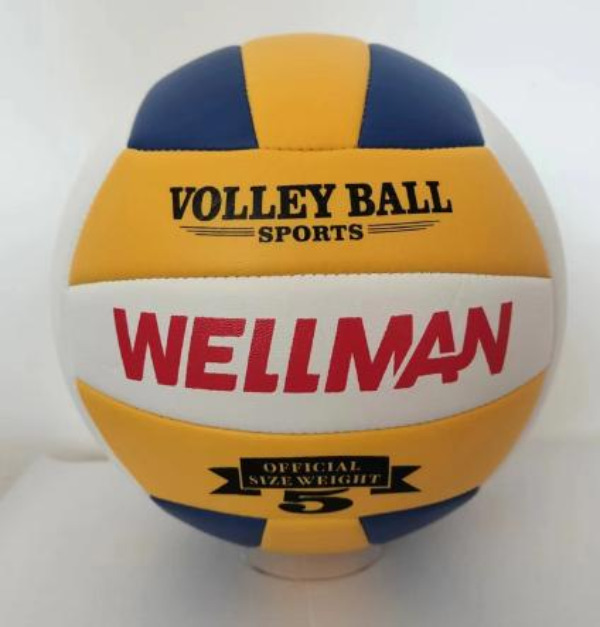

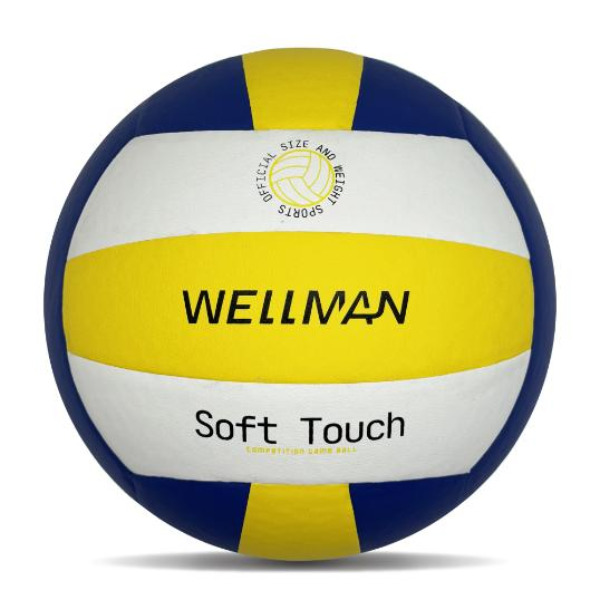

● Machine-Applied Version: Hangzhou Meidong’s Core Professional Line

WELLMAN machine-applied volleyballs are Hangzhou Meidong Sports’ core flagship product line. Leveraging the equipment advantages of the company’s own CNC production workshop, it employs an advanced process of “precision machine application + hot-melt reinforcement,” achieving full CNC automation in the core processes:

Custom Fabric Cutting: Utilizing Hangzhou Meidong Sports’ exclusive high-toughness PU leather (customized in collaboration with upstream suppliers), it is cut into 12 high-precision panels, with pre-reserved hot-melt adhesive grooves at the edges;

Automated Machine Application and Assembly: The panels are precisely aligned using the company’s imported CNC patching machine (seam error ≤0.2mm), with simultaneous edge hot-melt reinforcement, replacing traditional stitching;

Brand-Specific Treatment: A wear-resistant and anti-slip coating is applied, and the texture is ergonomically designed to enhance grip friction during passing and spiking;

Professional-Grade Testing: Each ball undergoes a 72-hour airtightness test and an 8000-impact rebound test before leaving the factory.

This product line is characterized by high splicing precision, smooth seams, and an 8% lower elasticity decay rate than ordinary sewn models, making it an advanced solution that balances professional experience with cost.

II. Performance Testing: Differences in Craftsmanship as Seen Through On-Field Experience

Clear differences were observed in on-field performance, primarily in three dimensions:

● Flight Stability

Stitched Version: Rippled seams result in uneven wind resistance distribution, leading to slight trajectory deviations of ≤5° during high-speed shots;

WELLMAN Machine-Mounted Version (Hangzhou Meidong Core Line): Precise panel fit and even wind resistance distribution improve stability by approximately 18% compared to the standard stitched version.

● Ball Contact Feel

Stitched Version: The seams feel rough to the touch, resulting in a “stiff” feel upon contact, which can cause hand irritation with prolonged high-frequency use;

WELLMAN Machine-Mounted Version (Hangzhou Meidong Core Line): Custom-made PU leather with moderate softness and hardness provides a high degree of fit to the contact area, resulting in a soft touch and clear feedback.

● Durability Performance

Sewn Type: The seams are prone to wear and tear, and are easily aged and peeled under high-frequency training. Lifespan is approximately 3-6 months.

WELLMAN Machine-Applied Type (Hangzhou Meidong Core Line): Heat-fused reinforced seams + anti-abrasion coating, less prone to cracking, lifespan is approximately 10-14 months.

III. Scenarios Adapted: Hangzhou Meidong’s Dual Product Lines Precisely Match Needs

Sewn-on and WELLMAN machine-applied volleyballs cater to different usage scenarios and user groups:

● Sewn-on version: Suitable for basic daily training on campus, beginners getting used to the ball, and low-frequency leisure activities, emphasizing high cost-effectiveness; supports bulk purchases by campus clubs and amateur clubs, and offers basic packaging customization;

● WELLMAN machine-applied version (Hangzhou Meidong’s core line): Suitable for amateur competitions, advanced training in clubs, and long-term, high-frequency players, balancing professional experience and durability; in addition to the standard version, small-batch team logo customization services are also available.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى 中文简体

中文简体