In the shopping list for volleyball equipment, “material type” is one of the core elements that determine the actual playing experience. From the classic rubber ball to the mainstream PU ball, and the modern seamless heat-pressed ball, volleyballs made of different materials have significant differences in manufacturing process, performance, and applicable scenarios. Hangzhou Meidong Sporting Goods Co., Ltd., a company specializing in the production of professional-grade volleyballs, features its WELLMAN brand, which focuses on high-quality PU machine-stitched volleyballs, precisely meeting the needs of advanced players. This article will break down the “design language” of these three types of volleyballs and analyze the advantages of WELLMAN’s professional PU machine-stitched volleyballs, helping you accurately choose the ball that suits your needs.

1. Manufacturing Process: From “Basic Molding” to “Seamless Integration”

The material type directly determines the molding process and texture of the volleyball, serving as a core distinguishing feature between different models.

● Rubber Model: The “Classic Template” of Volleyballs

The rubber model is the classic design of traditional volleyballs (natural rubber/synthetic rubber base material). The mainstream process is “compression molding and vulcanization,” with the core steps including:

1. Base Material Mixing: Mixing natural rubber with reinforcing agents, vulcanizing agents, and other raw materials, and pressing it into a rubber sheet;

2. Compression Molding: Placing the rubber sheet into a mold, vulcanizing at 150-180℃, and pressing it into a single volleyball shell;

3. Accessory Assembly: Attaching the air valve, inflating to test airtightness, and finally polishing the surface texture.

This process is characterized by lower cost and adequate basic elasticity, but the surface texture is rough, and it is prone to peeling, aging, and hardening after prolonged use.

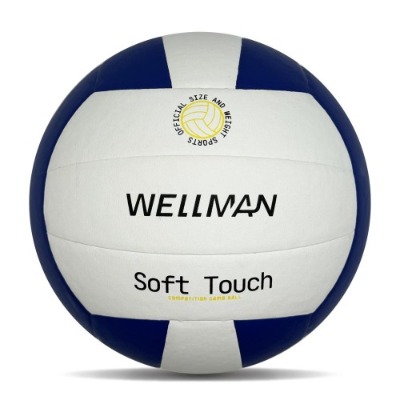

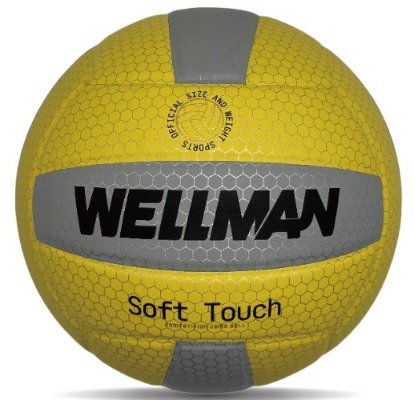

● PU Version: A Transitional Choice from Beginner to Advanced (WELLMAN Professional-Grade Main Model)

As the flagship product of Hangzhou Meidong Sporting Goods Co., Ltd.'s WELLMAN brand, the PU machine-attached volleyball is a core model in the current mass-market advanced segment (WELLMAN custom PU synthetic leather fabric + high-elastic butyl rubber inner bladder). The core process has been upgraded to “precision machine attaching + hot-melt reinforcement,” differing from traditional sewn models with a more refined process:

1. Custom Fabric Cutting: Using WELLMAN’s exclusive high-toughness PU leather, cut into 12 high-precision panels, with pre-drilled hot-melt adhesive grooves at the edges;

2. Automated Machine Attaching and Assembly: The panels are precisely aligned and attached using a CNC attaching machine, with simultaneous edge hot-melt reinforcement, resulting in a seam error ≤0.2mm;

3. Exclusive Brand Treatment: Sprayed with a WELLMAN anti-slip and wear-resistant coating, the texture features an ergonomic design to enhance grip friction during passing and spiking;

4. Professional-grade testing: Each ball undergoes a 72-hour airtightness test and a 6000-impact rebound test before leaving the factory.

This model (WELLMAN PU machine-applied volleyball) boasts a significantly higher splicing precision than traditional stitched PU Leather Volleyball Ball, and its elasticity decay rate is 8% lower than ordinary PU balls, making it an “advanced choice” that balances professional experience with cost-effectiveness.

● Seamless Hot-Pressed Version: The “High-End Professional Version” of Modern Volleyball

The seamless hot-pressed version is the mainstream design for professional competitions (high-polymer composite fabric + high-elastic bladder). Its core technology is “hot-press seamless bonding,” and the process includes:

1. Fabric Pre-cutting: The composite fabric is cut into large, irregularly shaped sheets, and hot melt adhesive is applied to the edges;

2. High-Temperature Hot-Pressure Molding: The sheets are placed in a custom mold, and under 130-160℃ high temperature and constant pressure, the edges of the sheets are hot-melted to form a seamless structure;

3. Precision Adjustment: After implanting the high-elastic bladder, the roundness is calibrated (error ≤ 0.3mm) and a surface anti-slip coating is applied.

This version has a seamless, spliced surface with a uniform and delicate touch, completely eliminating the airtightness issues of sewn versions, making it the preferred style for professional competitions and advanced training.

2. Performance: Higher-grade materials result in a smoother experience

Differences in materials directly translate into differences in performance on the field, primarily in three dimensions:

1. Flight Stability

- Rubber Version: Rough surface texture, uneven wind resistance, prone to slight trajectory deviation at high speeds;

- WELLMAN PU Machine-Mounted Version: Precise panel fit, uniform wind resistance distribution, stability improved by approximately 12% compared to the ordinary PU version;

- Seamless Hot-Pressed Version: Seamless and smooth surface, flight trajectory accuracy meets professional competition standards.

2. Touch Experience

- Rubber Version: Hard and rough surface, a “stiff” feel upon contact with the ball, prone to hand abrasion with prolonged use;

- WELLMAN PU Machine-Mounted Version: Custom PU leather with moderate softness, high fit in the contact area, soft touch and clear feedback;

- Seamless Hot-Pressed Version: Seamless and uniform material, consistent and delicate touch upon contact with the ball, precise passing and slamming feedback.

3. Durability

- Rubber version: Prone to aging and peeling under high-frequency training; lifespan approximately 3-6 months.

- WELLMAN PU machine-applied version: Heat-fused reinforced seams + wear-resistant coating; not prone to cracking; lifespan approximately 10-14 months.

- Seamless heat-pressed version: Composite fabric + seamless structure; strong tear resistance; lifespan approximately 15-20 months.

3. Recommended Application Scenarios: Precisely Matching Your Needs

- Choose Rubber Version: For basic daily training on campus, and for beginners to get a feel for the ball;

- Choose WELLMAN PU Machine-Applied Version: Professional-grade PU machine-applied volleyballs produced by Hangzhou Meidong WELLMAN, suitable for amateur competitions and advanced training in clubs;

- Choose Seamless Hot-Pressed Version: For professional team training, professional competitions, and advanced enthusiasts to improve their skills.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى 中文简体

中文简体