From Natural Hide to High-Tech PU: The Evolution of Leather Basketballs in Modern Play

Basketball has evolved dramatically over the decades, and nowhere is this transformation more tangible than in the materials used to make the ball itself. Long gone are the early days when genuine leather basketballs dominated courts, absorbing sweat, moisture, and sometimes even warping with age. While natural leather had its place in history, today’s game demands higher consistency, durability, and performance — all areas where advanced materials like PU leather and microfiber leather have taken the lead.

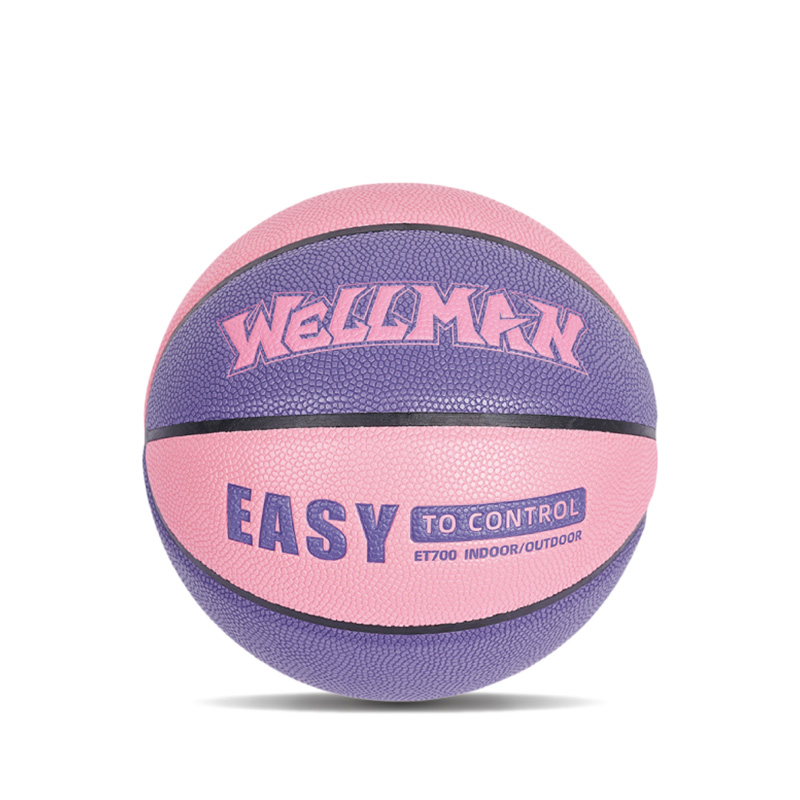

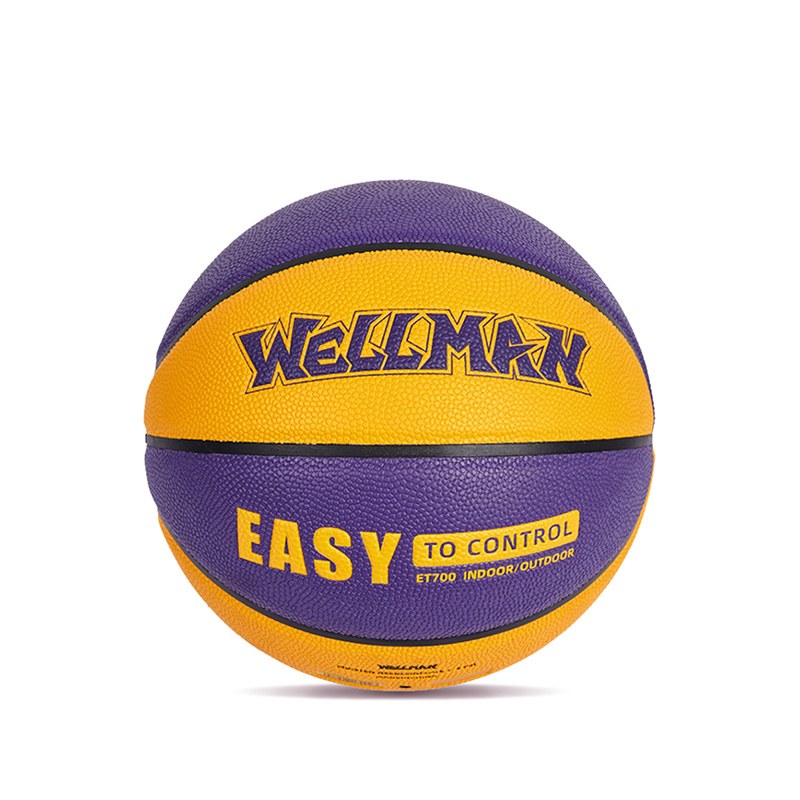

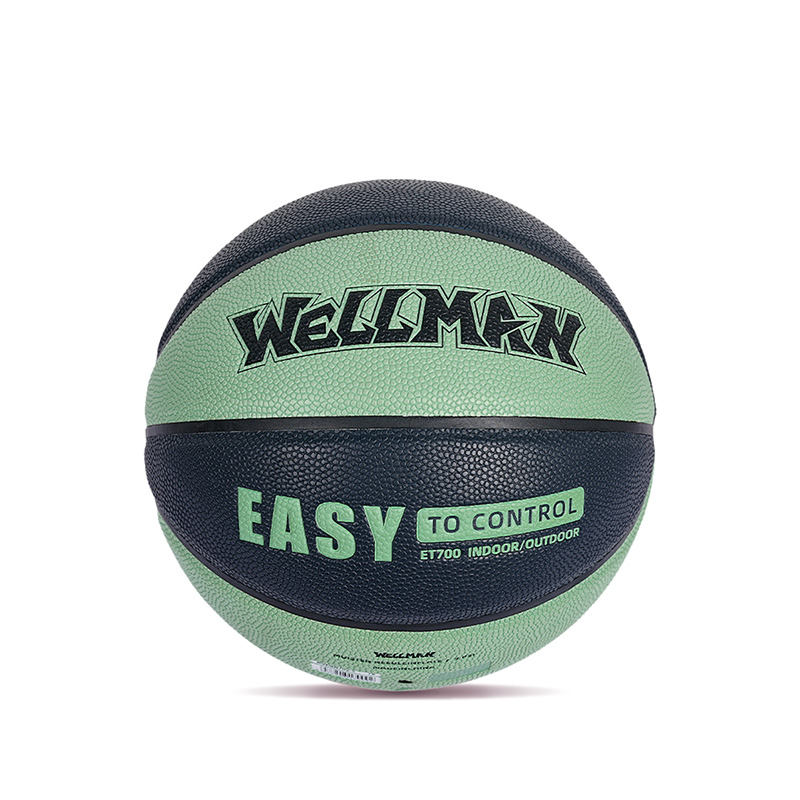

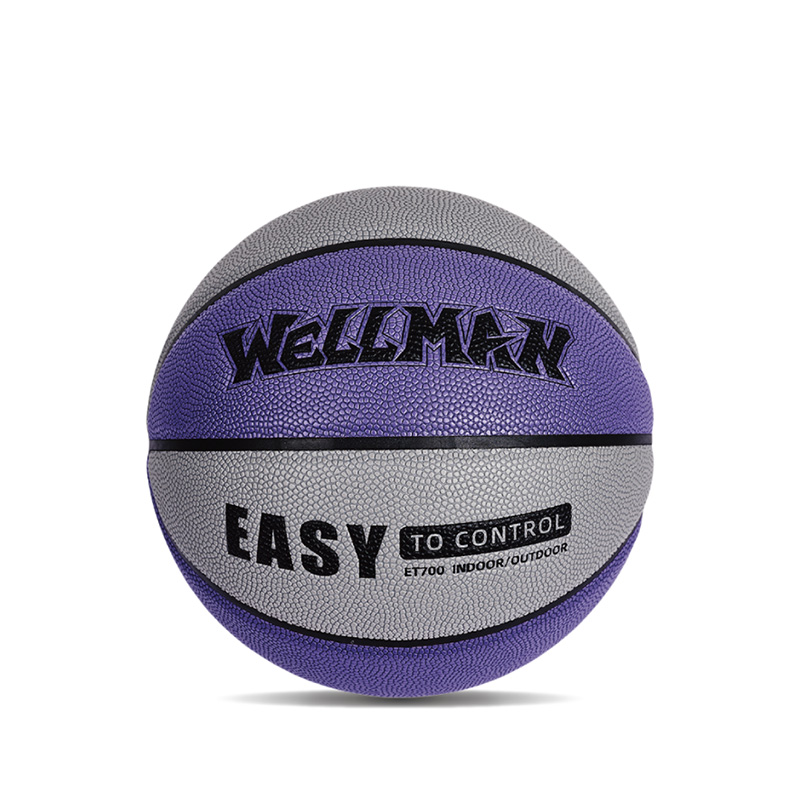

The shift from traditional leather to synthetic alternatives didn’t happen overnight. Early experiments with composite materials were inconsistent, but rapid progress in polymer science and textile engineering has led to the rise of PU leather basketballs that not only mimic the feel of real leather but also surpass it in critical aspects like weather resistance and uniformity. These materials are engineered for control and comfort, offering players the same tactile feedback in the hundredth shot as in the first, regardless of whether they play indoors or outdoors.

One of the pivotal advantages that PU leather brings to basketball manufacturing is consistency. Genuine leather, by nature, has variability — grain patterns, porosity, and thickness differ across hides. In contrast, PU leather can be precisely engineered with controlled surface textures and layered construction, ensuring every ball meets tight manufacturing specifications. This allows suppliers like us to deliver consistent quality across batches, which is essential for clubs, schools, and event organizers ordering in volume.

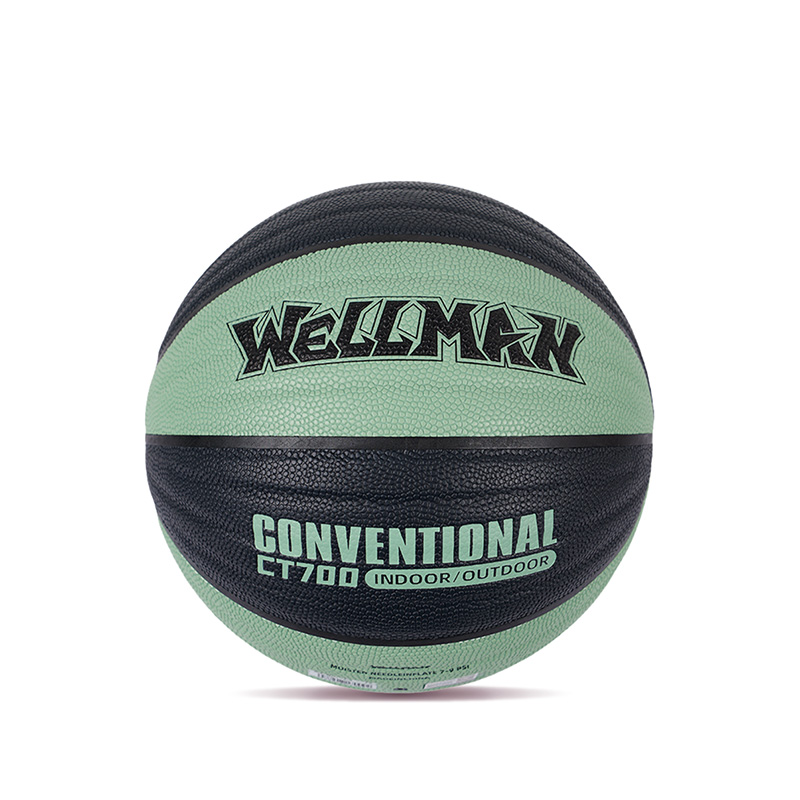

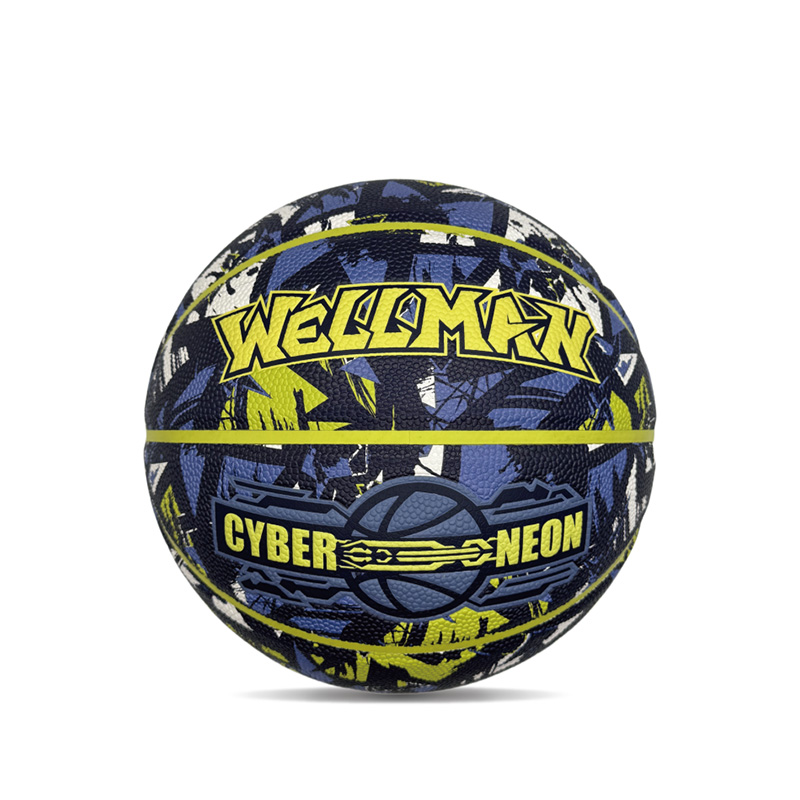

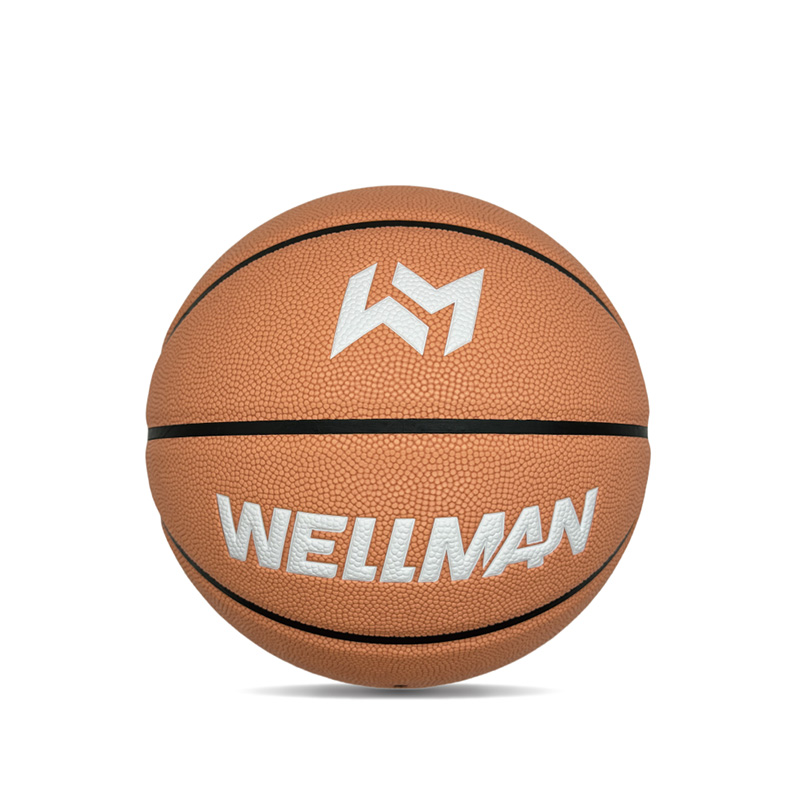

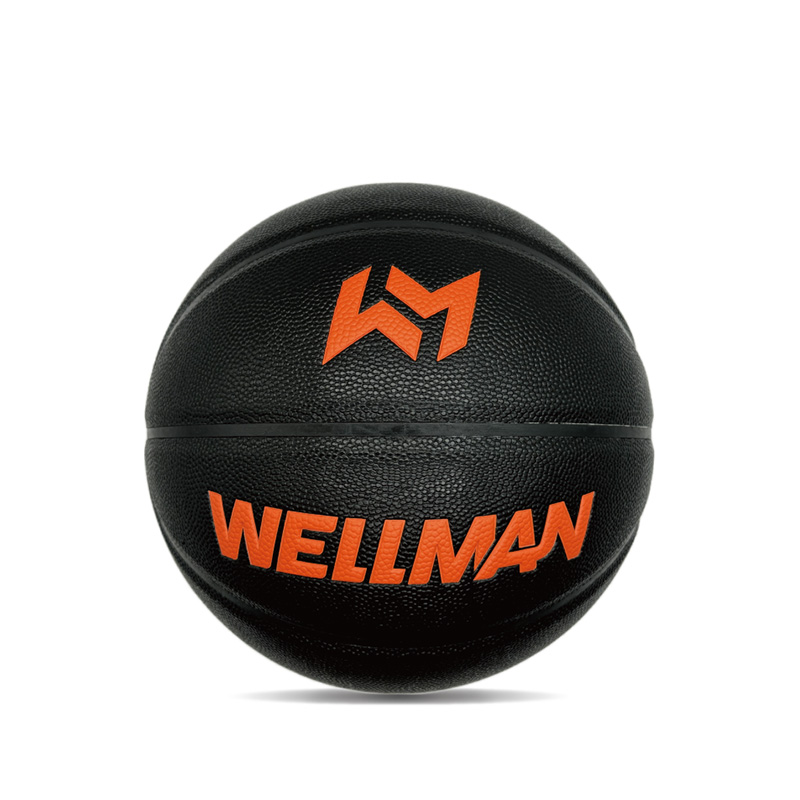

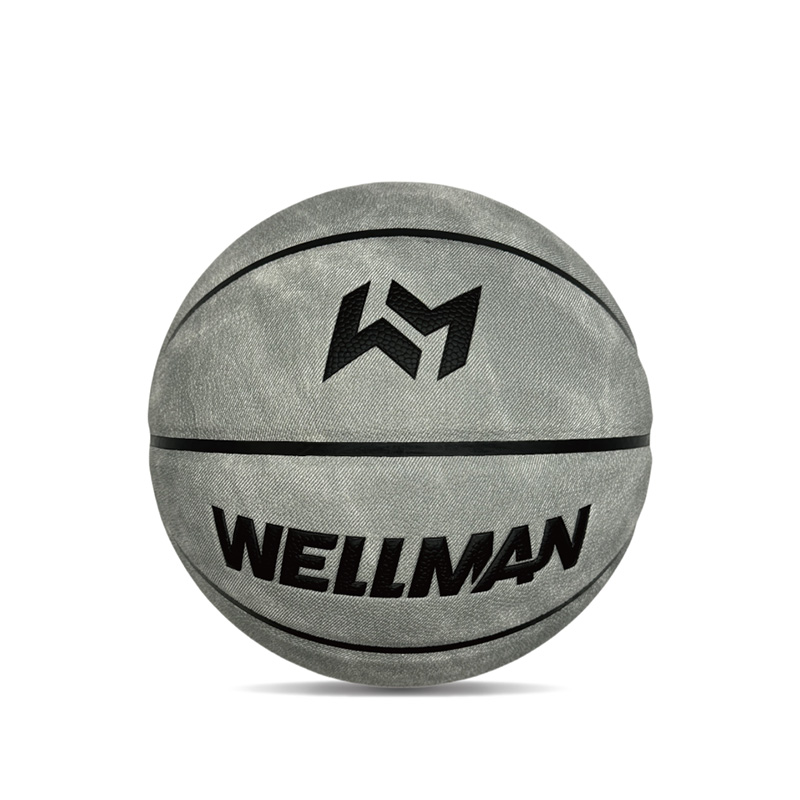

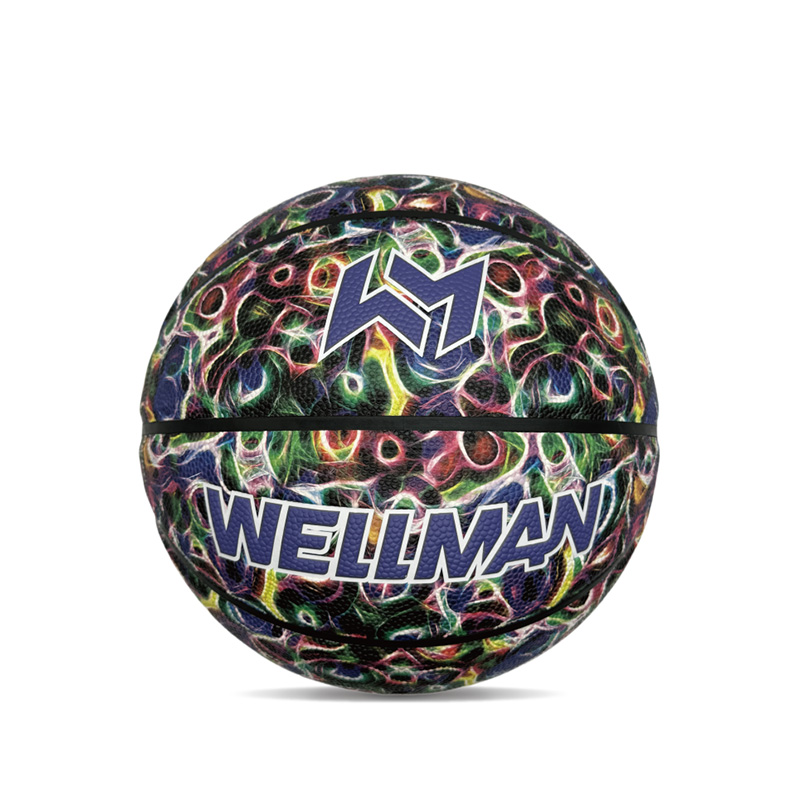

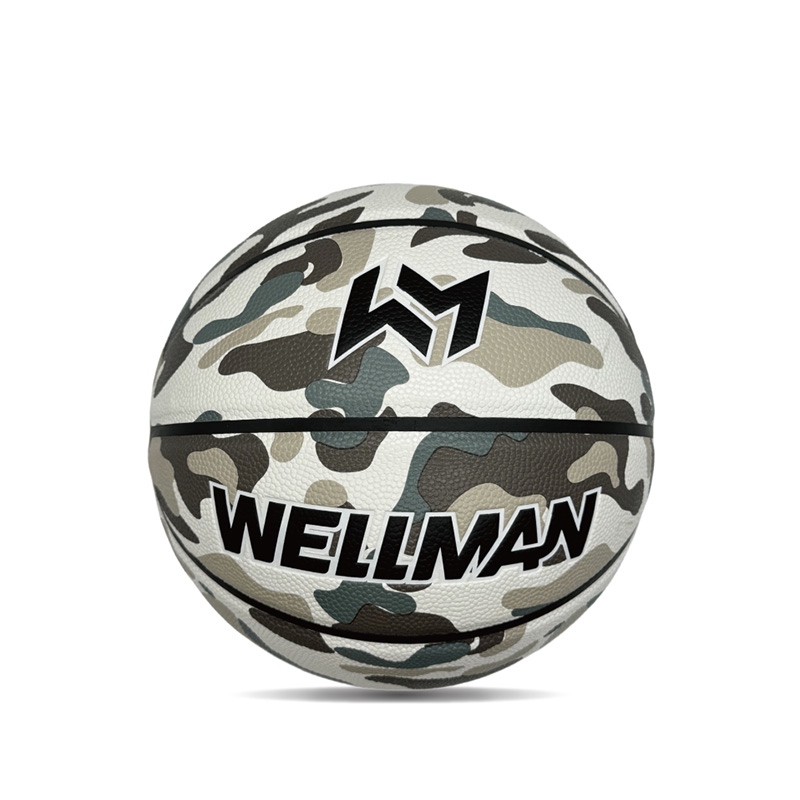

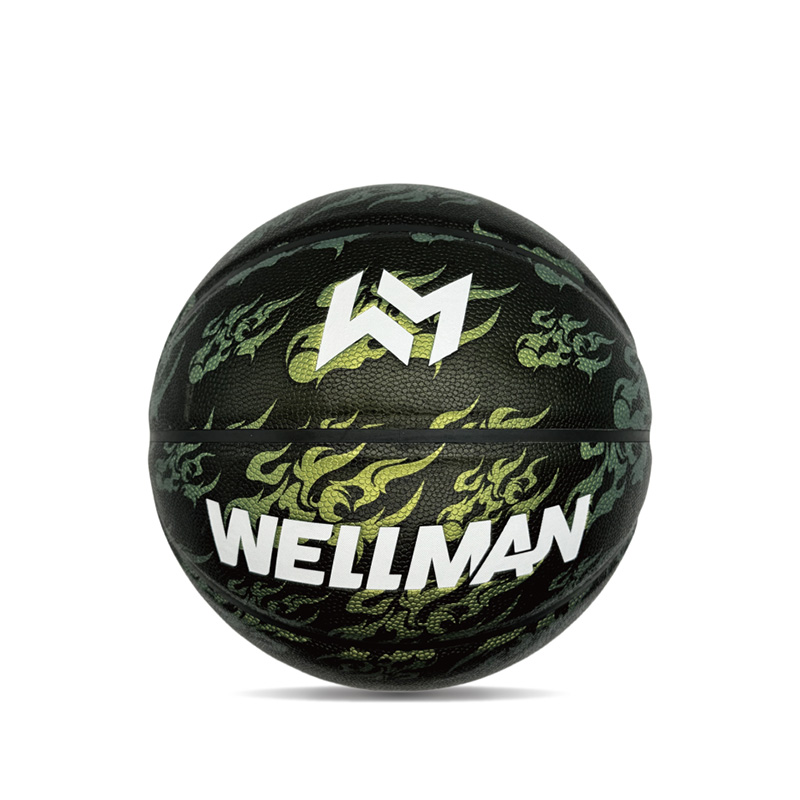

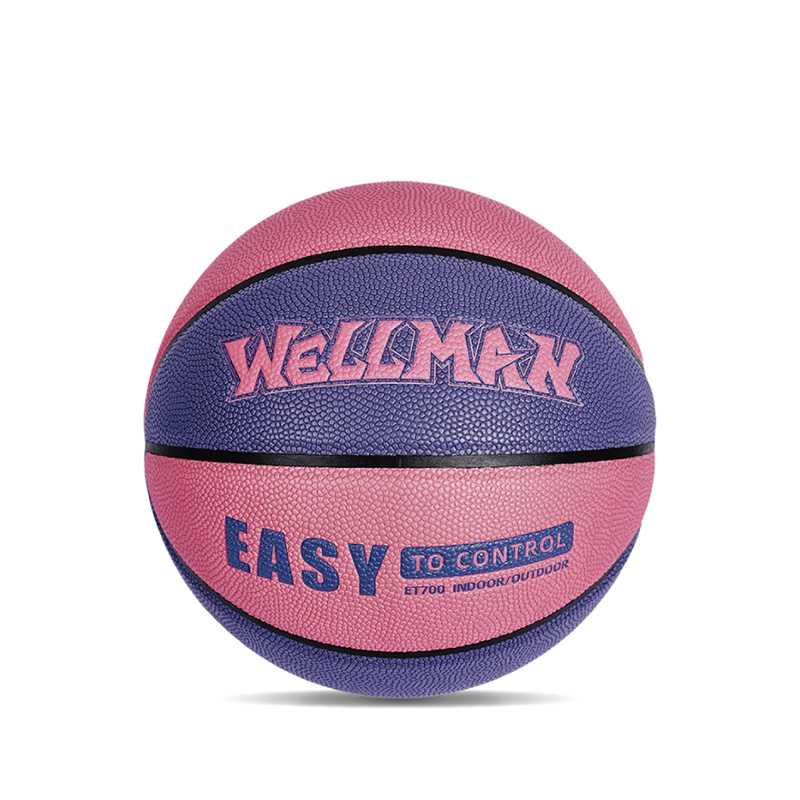

As the game itself becomes faster and more analytical, the demand for high-performance gear has also surged. That’s why we see not only professional leagues but also amateur organizations increasingly investing in synthetic leather basketballs for training and competition. From the stitching pattern to the weight distribution, every component contributes to how a ball performs during high-speed dribbles or spin-controlled layups. Even for team basketballs with logo customization, PU leather provides a stable surface for printing or embossing that won't degrade easily with use — a perfect fusion of branding and performance.

The rise of custom team basketballs has further accelerated the adoption of synthetic materials. A smooth, durable surface allows for precise application of team logos, sponsor marks, and event branding without compromising grip or aesthetics. Whether for tournaments, school leagues, or promotional events, a leather basketball that carries a team’s identity has become more than just sports equipment — it's part of a larger brand story. Our production methods ensure that the logos are not just printed but integrated in a way that stands up to rough play and frequent handling.

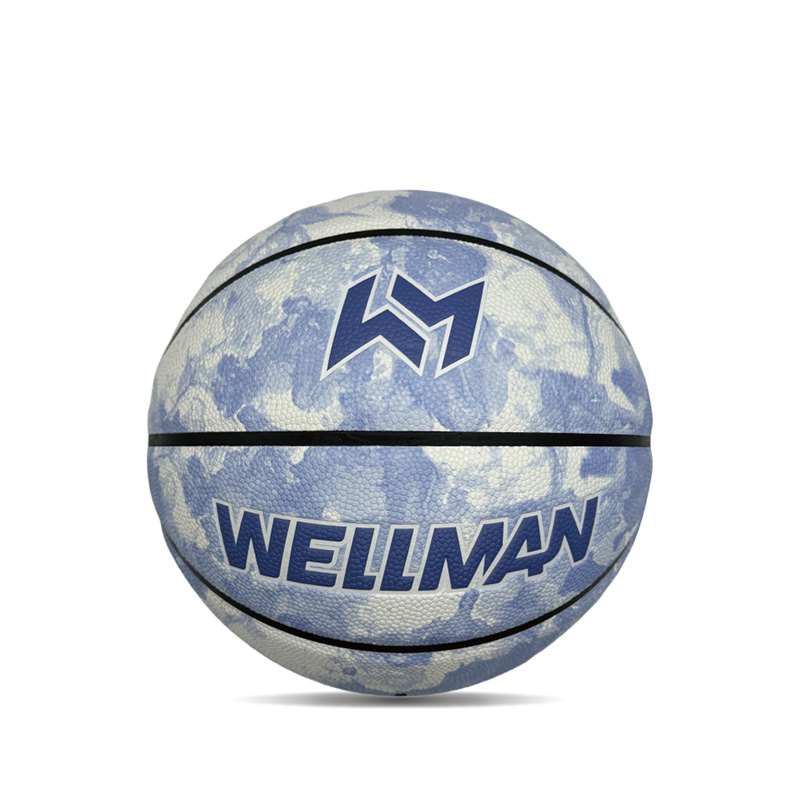

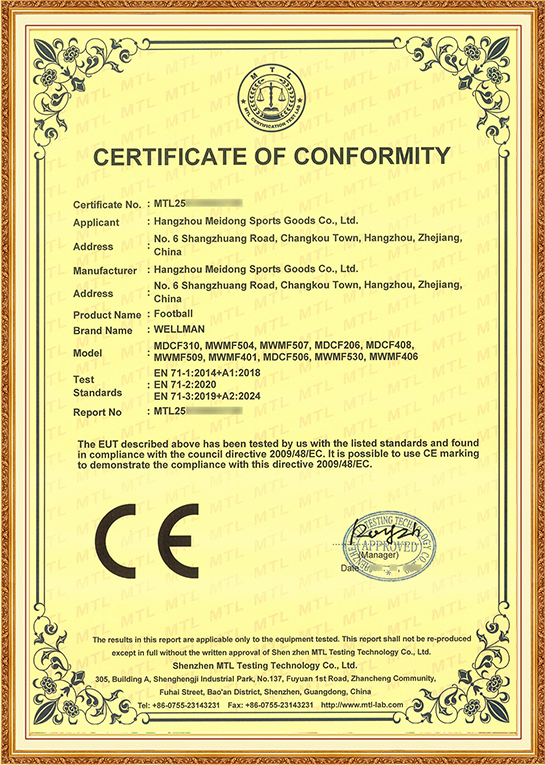

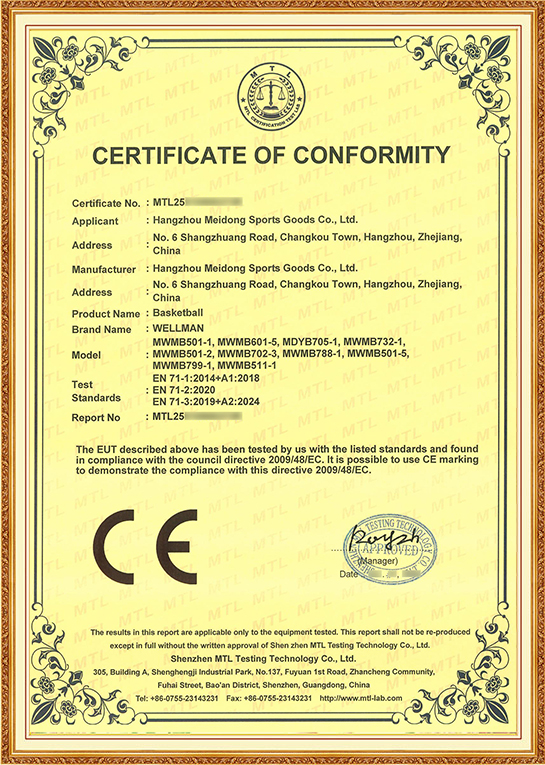

From a manufacturer's perspective, the transition to PU and microfiber leather has also improved sustainability and efficiency. Unlike animal hides, synthetic leather can be produced with less waste, and modern production lines allow for tighter quality control and faster turnaround times. While traditionalists may still favor the “classic” feel of natural leather, the reality is that today's top-tier PU leather basketballs meet or exceed performance expectations in nearly every measurable category — a shift that reflects both market demand and technological progress.

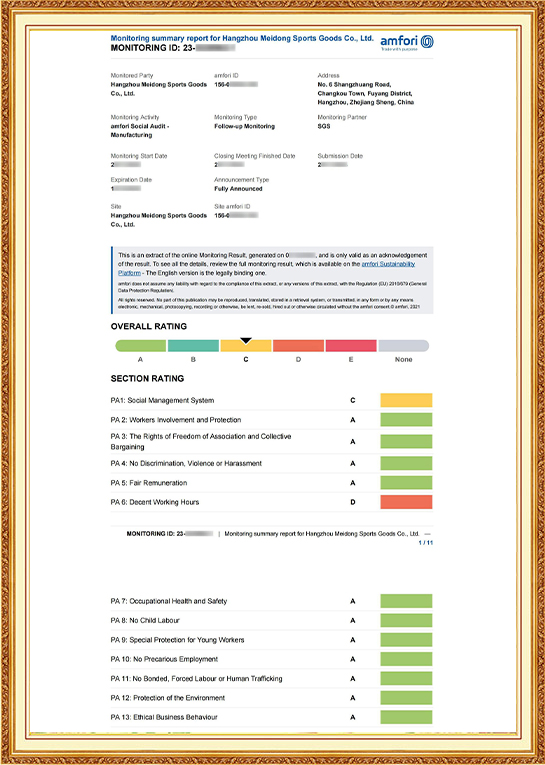

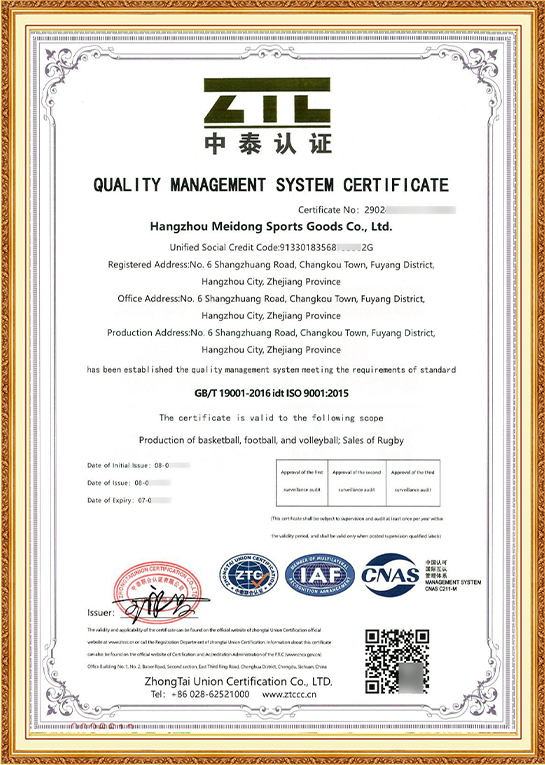

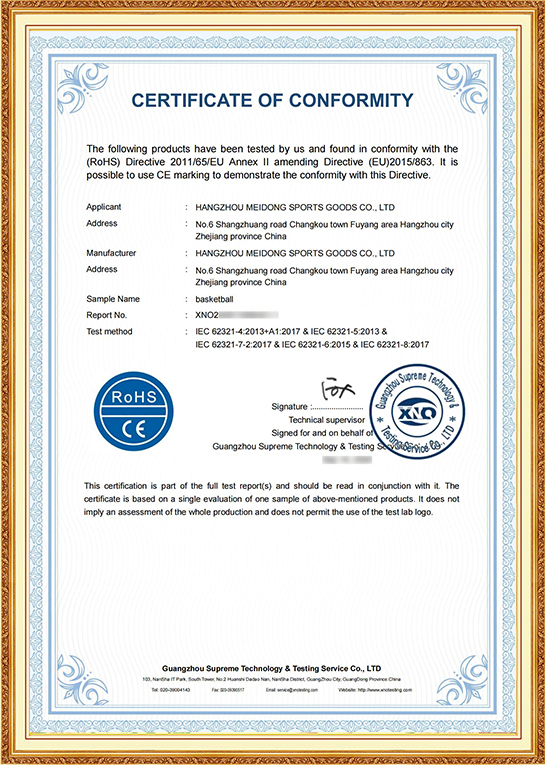

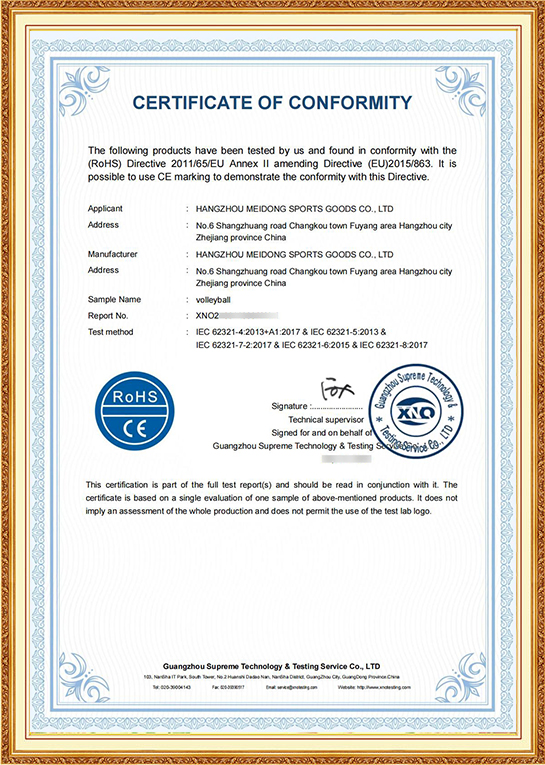

For businesses looking to offer quality, durability, and customization in one package, embracing the evolution of leather basketballs isn't just practical — it's necessary. Whether you're sourcing team basketballs with logo options for a regional league or need premium PU leather basketballs for a retail line, understanding the material evolution behind these products gives you an edge. At Meidong, we’ve invested in every stage of this evolution, ensuring that our leather basketballs reflect not only the heritage of the game but also the innovations shaping its future.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى 中文简体

中文简体