Volleyball has grown into one of the most widely played sports in the world, both indoors and on the beach. As the sport has evolved, so too has the equipment, with manufacturers constantly seeking materials and designs that enhance performance, durability, and player comfort. Among the most popular choices for volleyball construction today is polyurethane, commonly referred to as PU leather. A question that frequently arises for both casual players and professional athletes is whether PU leather volleyball balls are truly resistant to tear or scuffing.

Understanding PU Leather in Volleyball Construction

PU leather is a synthetic material designed to replicate the look and feel of natural leather while offering greater flexibility and resistance to environmental wear. Unlike genuine leather, which requires heavy maintenance and can deteriorate when exposed to moisture or sunlight, PU leather is engineered to resist these conditions. It is made by coating a fabric backing with polyurethane, creating a surface that is smooth, resilient, and adaptable.

In volleyballs, PU leather is highly valued for several reasons. First, it provides a soft yet durable touch, ensuring that players do not experience excessive discomfort during repetitive contact. Second, it delivers an excellent grip that allows athletes to maintain control whether they are passing, setting, or spiking. Finally, PU leather’s synthetic composition offers enhanced resistance to tearing and scuffing, especially when combined with thermal bonding or reinforced stitching.

Durability of PU Leather Volleyball Balls

When evaluating whether PU leather volleyballs are resistant to tear or scuffing, it is important to consider how the ball will be used. An indoor volleyball used primarily on smooth hardwood floors will face less abrasive contact than a ball used outdoors on concrete or rough sand. PU leather is designed to withstand both conditions better than traditional PVC materials.

The durability comes from the structure of the polyurethane itself. Polyurethane is flexible enough to absorb impact yet firm enough to retain shape. Unlike cheaper plastics that become brittle with repeated use, PU retains its integrity over time. This means that even after countless serves, spikes, and defensive dives, the ball resists cracking or peeling.

Additionally, PU leather volleyballs are often constructed with multiple layers beneath the outer shell. These internal reinforcements add stability and help the ball maintain its roundness. When combined with thermal bonding technology, the outer panels are fused without visible seams, reducing weak points that could otherwise split under pressure.

Resistance to Scuffing

One of the most common forms of wear on volleyballs is scuffing, caused when the ball slides across rough surfaces or comes into contact with shoes, floors, and even outdoor elements like rocks or sand. PU leather excels in this area because of its abrasion-resistant qualities.

The surface of PU leather volleyballs is engineered to be both smooth and slightly textured. This balance reduces friction during play, lowering the likelihood of visible scuff marks. Furthermore, PU leather’s surface coating is designed to repel dirt and stains, which means that any marks that do appear are easier to clean compared to other materials.

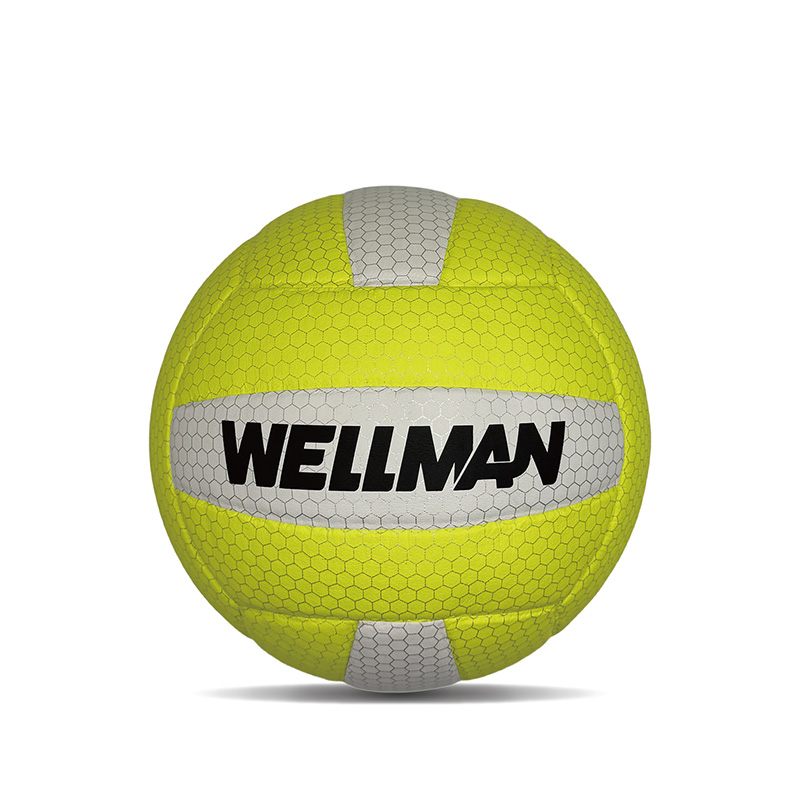

Scuffing is also minimized by the honeycomb or patterned textures integrated into many PU leather volleyballs. These designs not only enhance grip but also distribute the force of impact more evenly, reducing concentrated stress on any single area of the ball’s surface.

Tear Resistance in Competitive Environments

Tearing is a more severe form of damage compared to scuffing. It typically occurs when a material is too thin, too brittle, or poorly constructed. PU leather, however, is specifically developed to avoid these weaknesses.

In competitive volleyball environments, balls endure high-impact strikes from powerful serves and spikes. PU leather’s elasticity allows it to absorb this energy without splitting. Furthermore, thermal bonding technology has revolutionized the way PU leather volleyballs are made. Instead of relying on stitches that can unravel, thermal bonding fuses the panels together seamlessly. This not only improves waterproofing and airtightness but also significantly enhances tear resistance.

Even when exposed to outdoor conditions, such as sand moisture or heat, PU leather maintains its integrity. While no material is entirely indestructible, PU leather volleyballs outperform PVC and other low-cost alternatives in resisting tearing during intense play.

Performance Features Supporting Durability

Durability is not the only advantage of PU leather volleyballs. Performance features work hand in hand with material strength to provide players with a reliable and enjoyable experience.

- Grip and Control: The slightly textured surface of PU leather improves ball handling, allowing players to control passes and spikes with greater precision.

- Shape Retention: Thanks to advanced bladder systems and layered construction, PU leather balls maintain their shape far longer than alternatives.

- Water Resistance: Thermal bonding and polyurethane’s inherent resistance to water ensure that the ball does not absorb moisture, which could otherwise weaken the material and cause premature tearing.

- Visibility: Many PU leather volleyballs now feature multi-color or fluorescent designs that improve visibility. While this may not directly impact tear resistance, it ensures consistent play by allowing athletes to track the ball’s spin and trajectory.

Practical Considerations for Players

For athletes and recreational players, the key consideration is how long the ball will last under regular conditions. While PU leather is resistant to scuffing and tearing, proper care is essential to maximize its lifespan.

- Avoid excessive exposure to harsh surfaces: Although PU leather is abrasion resistant, repeated play on extremely rough concrete can accelerate wear.

- Clean after use: A simple wipe-down with a damp cloth can prevent dirt from embedding in the surface.

- Store properly: Keeping the ball in a cool, dry place prevents environmental damage.

- Maintain air pressure: Overinflation stresses seams and surfaces, while underinflation can cause irregular bouncing and added strain.

By following these guidelines, players can extend the durability of their PU leather volleyballs, ensuring they continue to resist scuffing and tearing over many games.

Training and Recreational Value

PU leather volleyballs are not only for professional play. Their resilience and consistent performance make them ideal for training and recreational use as well. Beginners benefit from the soft yet durable feel, reducing discomfort when learning the game. Meanwhile, experienced players appreciate the precision that PU leather provides in high-level practice sessions.

Schools, clubs, and training academies often choose PU leather volleyballs because they strike the perfect balance between cost, durability, and playability. This makes them an excellent investment for organizations looking to equip large groups of players with reliable equipment that will not easily wear out.

The Role of Advanced Design Features

One of the standout features in modern PU leather volleyballs is the integration of unique surface patterns such as honeycomb textures. These patterns are not merely cosmetic. They distribute impact forces more efficiently, reduce localized stress, and contribute to long-term resistance against tearing and scuffing.

Thermal bonding further ensures that no weak points exist along stitched seams. Traditional stitched volleyballs often begin to fray at the seams after repeated use. In contrast, thermally bonded PU leather volleyballs maintain their structural integrity, even after extended outdoor play.

The inclusion of fluorescent or multi-color designs also serves a functional purpose. By improving visibility, players are able to react faster and strike more accurately, reducing unintentional collisions with surfaces that could otherwise contribute to wear.

Industry Trends and Player Preferences

Sports equipment manufacturers continue to innovate with PU leather volleyballs, recognizing the demand for long-lasting balls that perform consistently across diverse environments. Players increasingly prefer PU leather due to its comfort and resilience. Coaches and organizations value the reduced replacement costs that come with extended durability.

In addition, PU leather volleyballs align well with sustainability goals. Because they last longer than lower-quality balls, fewer replacements are required, reducing waste in the long run.

Final Thoughts

So, are PU leather volleyball balls resistant to tear or scuffing? The answer is a resounding yes. While no volleyball is completely immune to damage, PU leather offers a remarkable combination of durability, flexibility, and resistance to abrasion. Its tear resistance is enhanced by layered construction and thermal bonding technology, while its smooth yet textured surface minimizes scuffing and allows for easy cleaning.

From indoor courts to outdoor arenas, PU leather volleyballs deliver reliable performance without quickly succumbing to the wear and tear that often plagues lower-grade materials. For athletes, coaches, and recreational players alike, PU leather stands out as one of the most dependable materials available for volleyball construction.

Ultimately, choosing a PU leather volleyball means investing in a piece of equipment that not only withstands the test of time but also enhances the quality of play. Whether used in training, competition, or casual matches, it is a material designed to elevate the game while resisting the scuffs and tears that can cut short the life of lesser alternatives.

English

English русский

русский Español

Español Deutsch

Deutsch عربى

عربى 中文简体

中文简体